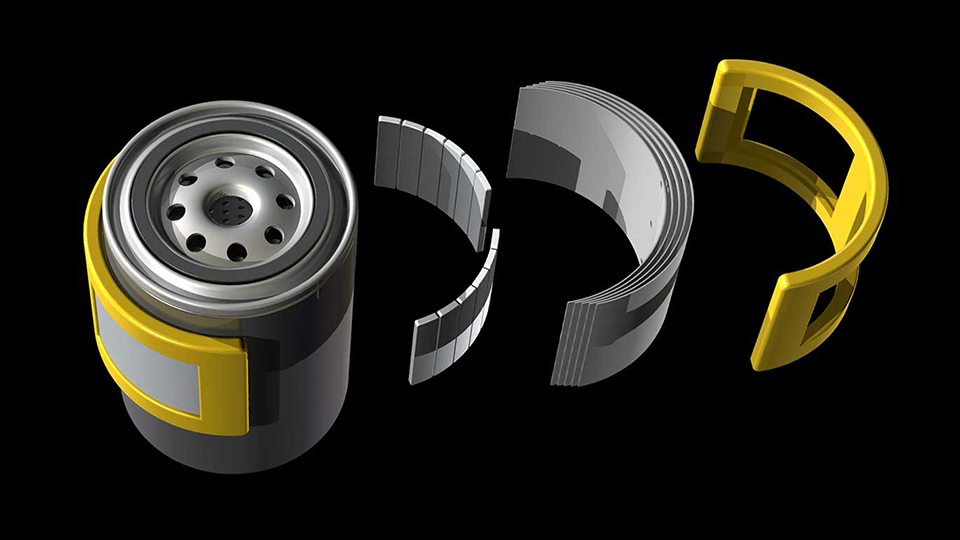

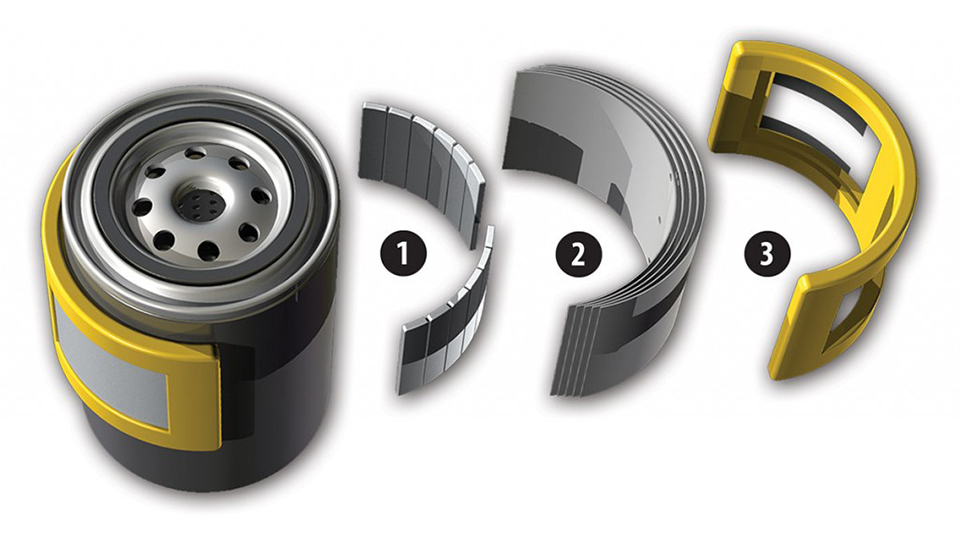

FilterMag Consumer Products

What do you ride or drive?

- Cars, Sports Cars, Street Rods

- Sport Trucks, Pickups, SUVs, RVs

- American Motorcycles

- Sport Bikes

- Boats, Watercraft, ATVs

- FilterMags go Racing

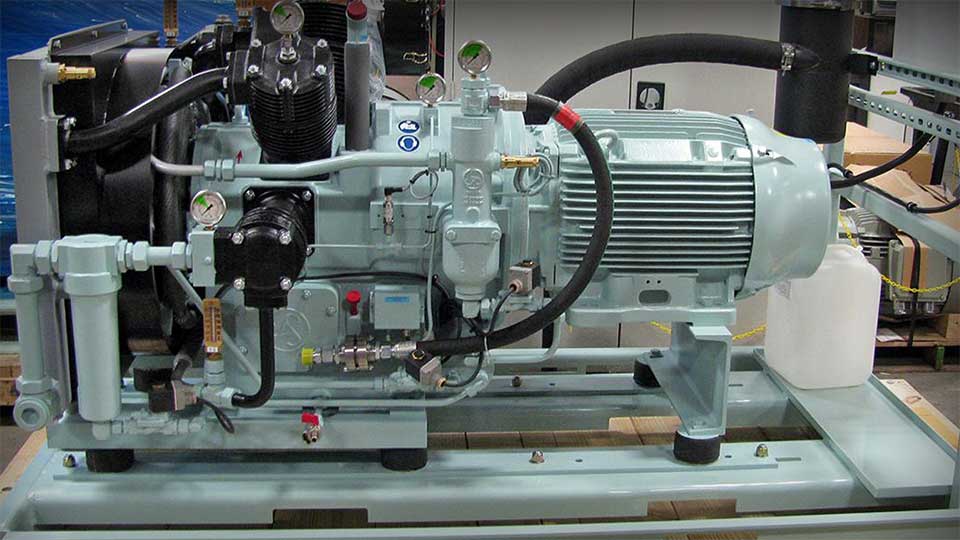

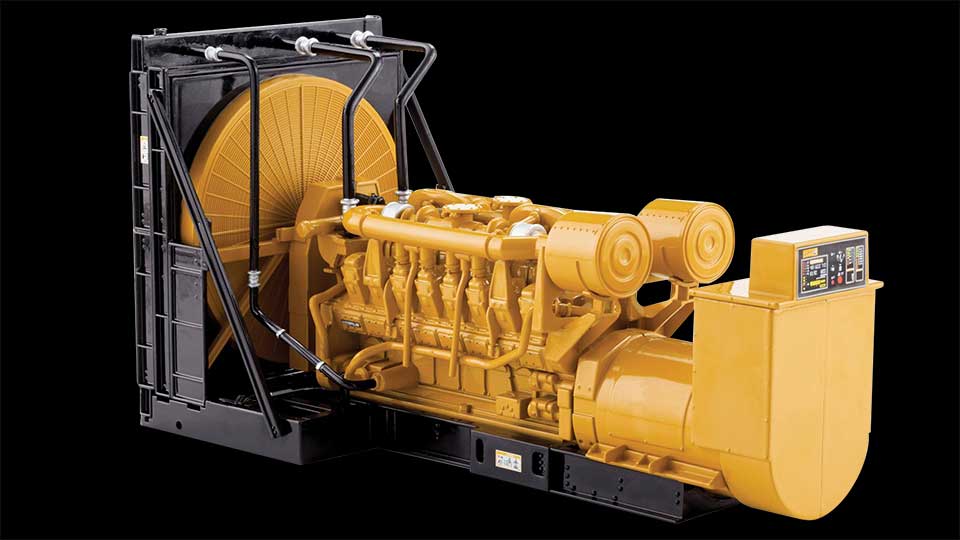

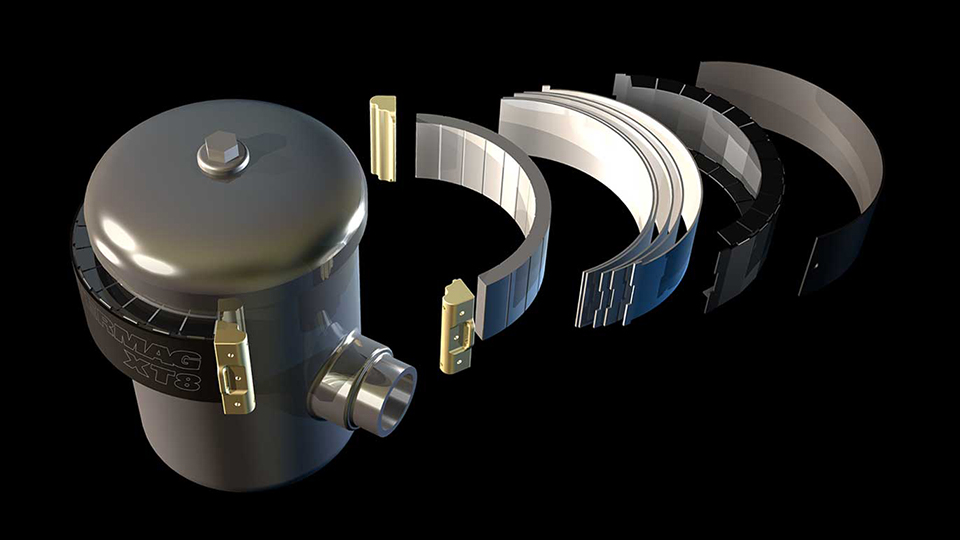

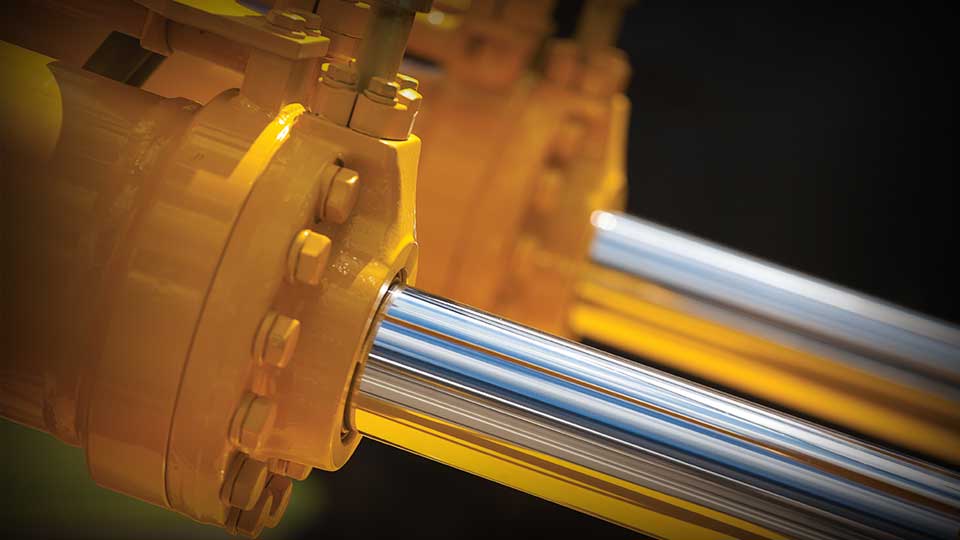

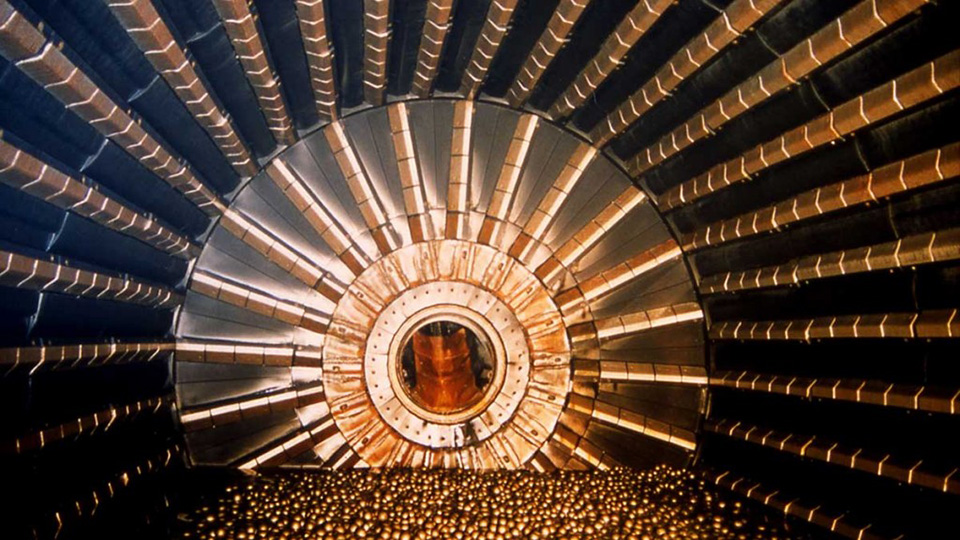

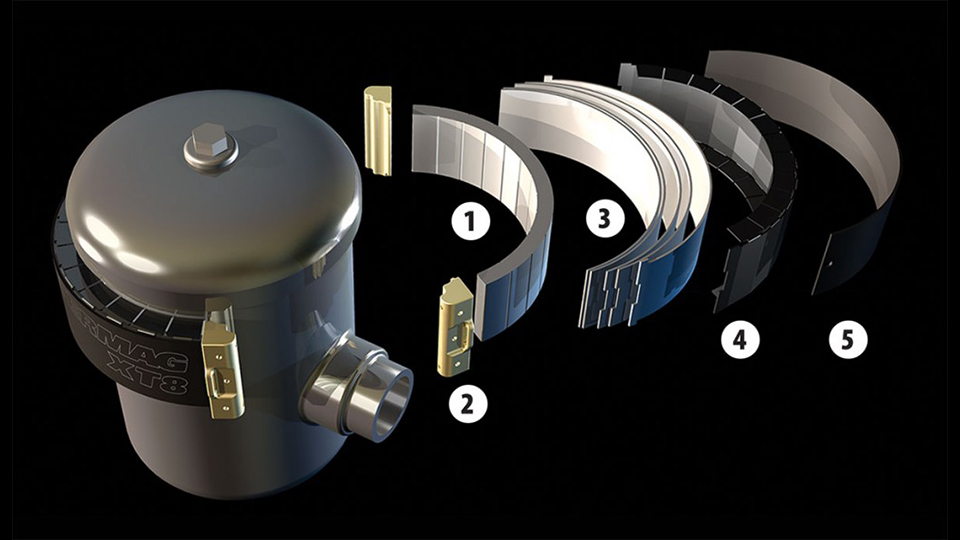

FilterMag Industrial Products

Cover your assets with FilterMag

- Engines

- Hydraulics

- Rotating Equipment

- Gear Boxes

Mining & Aggregates • Oil & Gas • Manufacturing & Processing