FILTERMAG

ABOUT FILTERMAG

- Powerful

- Focused

- Magnetic Fluid Filtration

HOW FILTERMAG WORKS

- Reduce Wear

- Mitigate Damage

- Increase Reliability

- Extend Equipment Life

- Increase profits

- Reduce downtime

- Improve oil filter efficiency

FILTERMAG INDUSTRIAL PRODUCTS

If your equipment isn’t working, you aren’t making money. FilterMag increases reliability, extends maintenance intervals and equipment life. When things do go wrong, FilterMag can mitigate damage that can make repairs go faster.

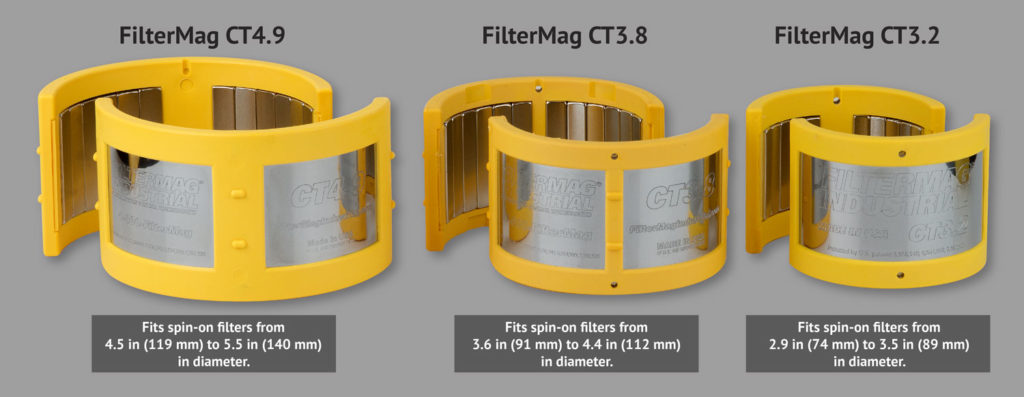

Industrial filters are constructed with thicker steel walls when compared to automotive filters. Our Industrial Products are designed with larger stronger magnets to allow enough magnetic force to penetrate the thick industrial filter walls to capture the small wear causing particles.

If we compare the FilterMag Industrial CT4.9 part to the consumer SS365 part the CT4.9 magnets are approximately 27% thicker, 14% taller, 13% wider resulting in 64% more magnet volume. The Industrial CT4.9 also uses stronger N42SH rated neodymium rare earth magnets instead of the consumer’s SS365 N40 magnets. Each Industrial CT4.9 part uses 12 larger stronger magnets compared to 8 magnets in the Consumer SS365 part. This results in an approximately 67% stronger magnet pulling force that penetrates the thicker steel used industrial oil filter walls. That much stronger force allows the capture of the wear causing small particles through the thicker walls of industrial filters. The consumer magnets do not generate enough magnetic force to penetrate the industrial filter walls and capture the smaller particles.

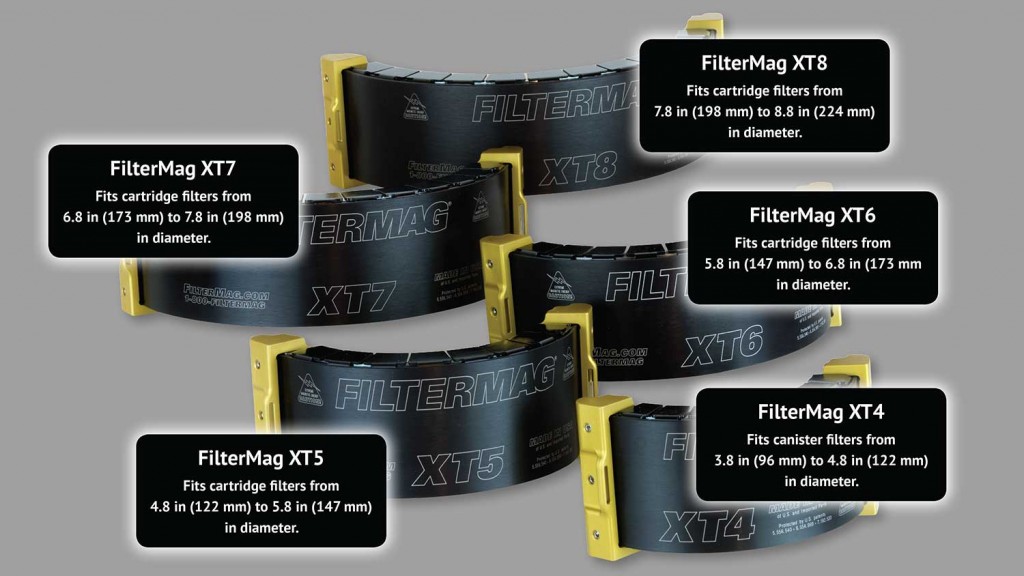

Our FilterMag Industrial XT parts are designed for canister filters. The magnets used in the XT parts are approximately 200% thicker (1/2”), 25% taller and 90% wider resulting in 650% more magnet volume and 610% more magnetic pull force than our Industrial CT4.9 parts. That incredible magnetic force penetrates the typical 1/4″ to 3/8” thick steel (or aluminum) canister filter walls to capture the small wear causing particles that pass through the filter medium. The magnets are so strong they are considered a permanent installation because they are virtually impossible to remove from a steel canister without destroying the FilterMag XT.

Our FilterMag Filter-Mag-Plugs are designed for use in gearboxes, transmissions, differentials and other equipment that may not have a replaceable filter. They are custom manufactured on our Hass CNC Lathe-Mill to fit into your equipment. They use the same powerful high temperature rated N42SH neodymium rare earth magnets used in the rest of our industrial products to capture and hold as many particles as possible. The Filter-Mag-Plug’s are made of corrosion resistant stainless steel and the magnets are encased in a stainless steel tube designed to last year after year.

Mining

Less Downtime - Faster Repairs

Oil and Gas

Increased Reliability - Damage Mitigation

Manufacturing

Proven Increases in Availability - Extended Fluid Life

Power Generation

Increased Reliability - Damage Mitigation

FilterMag Industrial Product

XT FOR CARTRIDGE FILTERS

Fixed Cartridge Filters Use FilterMag XTs

EXTREMELY POWERFUL, HEAT-RESISTANT NEODYMIUM ALLOY MAGNETS are engineered to focus a magnetic field inside your filter through the thick canister walls. Specifically formulated to remain effective in the most extreme environments, our magnets are guaranteed to remove particles from oil operating at up to 300ºF while most magnets start losing magnetism at 180ºF

FilterMag Industrial Product

CT FOR SPIN-ON FILTERS

Spin-on Filters Use FilterMag CTs

POWERFUL, HEAT-RESISTANT NEODYMIUM ALLOY MAGNETS are engineered to focus a magnetic field inside your industrial spin-on filter. Specifically formulated to remain effective in the most extreme environments, our magnets are guaranteed to remove particles from oil operating at up to 300ºF while most magnets start losing magnetism at 180ºF

FilterMag Industrial Product

FILTER-MAG-PLUGS

ENHANCED MAGNETIC FILTRATION PLUGS

Filter-Mag-Plugs (“FMP”) are custom made to order on our Haas dual spindle ST30-DSY lathe/mill. All FMPs are made from stainless steel and the threads can be made to fit most any application. All use N42SH neodymium rare earth magnets that will not lose magnetic force when they are heated in normal operations. They are rated to 300OF (150OC). There are 3 types of FMP’s tube types available and they are described below:

SMOOTH

Plain smooth tube regular drain plugs

CENTERING FINS

Tubes with centering fins only

CENTERING FINS WITH ENHANCEMENT RODS

The enhanced drain plugs with rods [all enhanced plugs also have centering fins].

Easy Installation • Cleaner Removal • Reusable

Tank-Mag

FilterMag Industrial Product

WATERMAG

WaterMag—Molecular Water Absorber

Finally, there is a simple, safe, inexpensive way to get the water out of your hydraulic systems. WaterMag uses patented zeolite technology to attract and hold water at the molecular level. The small pellets contained in each WaterMag are actually advanced technology water adsorbers when placed in lubricating oil or hydraulic fluid.

FILTERMAG CONSUMER PRODUCTS

Maximum Protection—Pair of SS or MC/MB FilterMags

Expose all of the engine oil flowing through the filter to Filtermag. This provides twice the opportunity for FilterMag to capture wear-causing particles in your oil.

Powerful Protection—Single SS or MC/MB FilterMag

Exposes half of the engine oil flowing through the filter to Filtermag. This provides some protection but many small damaging particles will continue to circulate through the oil causing wear.